2D Drawing & 3D Simulation are crucial tools in both mechanical and electrical engineering. They allow for precise visualization, analysis, and optimization of designs before physical production or construction. Offering these services provides a wide range of possibilities for clients across various industries. Here’s a breakdown of what services you can request on this platform with 2D Drawing and 3D Simulation in Mechanical and Electrical Engineering:

1. 2D Drawing Services (Mechanical and Electrical Engineering):

2D drawings are essential for documenting design specifications, dimensions, tolerances, and assembly instructions. They are used in manufacturing and production environments and act as the blueprint for engineers, manufacturers, and suppliers.

Mechanical Engineering:

Detailed Engineering Drawings: Create 2D technical drawings for mechanical components and assemblies, including views, sections, dimensions, and tolerances. These are used for manufacturing parts.

Examples: Gear components, structural parts, machinery, and consumer goods.

Assembly Drawings: Provide 2D assembly drawings that show how various parts fit together. This includes exploded views, parts lists, and assembly instructions.

Examples: Assembly of mechanical devices like pumps, motors, or machine tools.

Manufacturing Drawings: Prepare 2D drawings for fabrication, including detailed specifications for processes like welding, machining, casting, or sheet metal fabrication.

Examples: Fabricated frames, metal brackets, or chassis.

Piping and Plumbing Diagrams: Create 2D piping layout drawings for mechanical systems such as HVAC, water, and gas piping systems in buildings or industrial plants.

Examples: Plumbing systems, HVAC ducting, or industrial piping layouts.

Tolerancing and GD&T (Geometric Dimensioning and Tolerancing): Develop tolerances using GD&T in 2D to communicate design intents more accurately for complex mechanical components.

Examples: High-precision parts for the aerospace or automotive industry.

Production Drawings: Offer production-ready drawings for parts that can be directly handed off to the manufacturing floor for production, ensuring no errors in the process.

Electrical Engineering:

Wiring Diagrams: Produce 2D electrical schematics and wiring diagrams to show how electrical circuits and systems should be wired, including symbols and components.

Examples: Electrical circuits for industrial control panels, home automation systems, or electrical vehicles.

Circuit Layouts: Provide circuit design drawings that detail the layout and interconnection of electrical components like resistors, capacitors, and integrated circuits.

Examples: Circuit layouts for power supplies, motor controls, and sensors.

Panel Layouts: Design 2D layouts for electrical control panels, including the arrangement of electrical components such as circuit breakers, switches, and relays.

Examples: Electrical panel designs for factories, power plants, or industrial machinery.

Schematic Diagrams: Create schematic diagrams that show electrical components and their interconnections in simplified form, focusing on the flow of electricity.

Examples: Low voltage wiring for lighting, HVAC systems, or control systems.

Power Distribution Schematics: Provide power distribution diagrams showing how electricity is distributed across a facility or building, ensuring the electrical system functions properly.

Examples: Power distribution for commercial buildings, factories, or renewable energy systems.

2. 3D Simulation Services (Mechanical and Electrical Engineering):

3D simulations help visualize designs in a 3D environment, allowing for better understanding of the product’s behavior, performance, and potential issues before physical prototypes are created.

Mechanical Engineering:

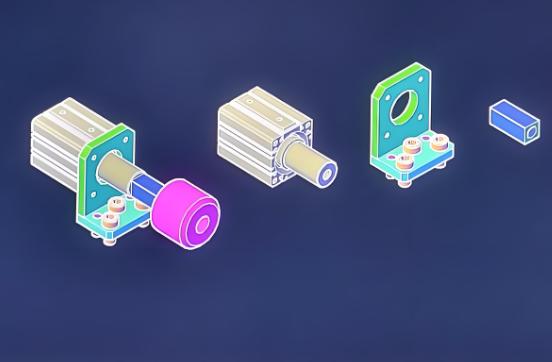

3D Modeling and Visualization: Create 3D models of mechanical components and assemblies to visualize and interact with the design before it is manufactured. These models can be used for presentations, marketing, and design validation.

Examples: Prototypes for consumer electronics, automotive parts, or industrial equipment.

Finite Element Analysis (FEA): Offer FEA simulations to analyze how parts or assemblies will perform under various conditions (e.g., stress, temperature, or pressure). This allows you to predict failure points and optimize the design.

Examples: Structural components of machinery, aerospace components, or automotive parts.

Thermal and Fluid Dynamics Simulation (CFD): Provide Computational Fluid Dynamics (CFD) simulations to analyze airflow, heat transfer, and fluid behavior in mechanical systems such as engines, HVAC systems, and pipelines.

Examples: Thermal management of electronics, heat exchangers, or ventilation systems.

Kinematic and Dynamic Analysis: Perform motion analysis to study how parts of a mechanism move, their interactions, and their response to forces.

Examples: Robotics, automotive suspension systems, or conveyor belts.

Design Optimization: Offer services that optimize 3D models to ensure minimal material usage while maintaining performance, strength, and cost-effectiveness.

Examples: Weight reduction for aerospace components or automotive parts.

Assembly Simulation: Use 3D simulations to test how mechanical assemblies will come together during manufacturing or assembly processes, ensuring ease of assembly and no interferences.

Examples: Complex machinery, automotive assemblies, or consumer products.

Prototyping and Testing: Create virtual prototypes using 3D simulations to test how the design will perform under real-world conditions (e.g., durability, temperature, or pressure).

Electrical Engineering:

Circuit Simulation: Perform 3D circuit simulations to predict electrical behavior, optimize designs, and test circuit performance before actual hardware is built. This includes testing for voltage, current, and power efficiency.

Examples: Power supply circuits, motor controllers, or signal processing circuits.

PCB (Printed Circuit Board) Design & Simulation: Offer PCB simulation to ensure that the layout of electrical components is optimal and that the board will function correctly. This can include thermal, electrical, and signal integrity analysis.

Examples: PCB designs for consumer electronics, medical devices, or automotive systems.

Electromagnetic Simulation: Provide electromagnetic field simulations to analyze the behavior of electric and magnetic fields in electrical systems, helping to design efficient and safe components.

Examples: Antenna design, motor coil design, or wireless charging systems.

Power System Simulation: Simulate the behavior of electrical power systems, such as grids or battery systems, to predict performance, load capacity, and fault analysis.

Examples: Power grid optimization, renewable energy systems, or backup power systems.

Motor and Generator Simulation: Simulate the behavior of electric motors and generators, optimizing their design for efficiency, power output, and performance.

Examples: Electric vehicle motors, industrial machines, or renewable energy generators.

Lighting Design and Simulation: Provide 3D lighting simulations to optimize the placement, intensity, and energy efficiency of lighting systems in various settings.

Examples: Building lighting design, streetlights, or industrial lighting.

3. Combined Services for Both Mechanical and Electrical Engineering:

Product Development:

Collaborative Product Design: Offer integrated design services where mechanical and electrical systems are designed together. This can include designing physical components and electrical systems in parallel to ensure compatibility and integration.

Examples: Consumer electronics (smartphones, laptops), automated machinery, or smart devices.

System Integration and Optimization: Help clients integrate mechanical and electrical subsystems into a cohesive final product. Simulate the interaction between mechanical systems (e.g., motors, actuators) and electrical systems (e.g., sensors, controllers) to optimize overall product performance.

Prototyping and Testing:

Virtual Prototyping: Use 3D modeling and simulations to create virtual prototypes that can undergo testing and validation before physical prototypes are built. This saves time and money by identifying design flaws early.

Functional Testing in Simulations: Use simulation tools to test and validate both mechanical and electrical functions in a virtual environment, ensuring that everything works together before moving to production.

Training and Support:

Simulation Training: Offer training services to clients or teams on how to use 3D simulation tools, enabling them to conduct their own analysis and tests for mechanical and electrical designs.

Support for Standards and Compliance: Provide support and ensure that designs meet industry standards, codes, and regulations for mechanical and electrical engineering systems, including compliance with safety, environmental, and energy-efficiency guidelines.

2D Drawing & 3D Simulation are crucial tools in both mechanical and electrical engineering. They allow for precise visualization, analysis, and optimization of designs before physical production or construction. Offering these services provides a wide range of possibilities for clients across various industries. Here’s a breakdown of what services you can request on this platform with 2D Drawing and 3D Simulation in Mechanical and Electrical Engineering:

1. 2D Drawing Services (Mechanical and Electrical Engineering):

2D drawings are essential for documenting design specifications, dimensions, tolerances, and assembly instructions. They are used in manufacturing and production environments and act as the blueprint for engineers, manufacturers, and suppliers.

Mechanical Engineering:

Detailed Engineering Drawings: Create 2D technical drawings for mechanical components and assemblies, including views, sections, dimensions, and tolerances. These are used for manufacturing parts.

Examples: Gear components, structural parts, machinery, and consumer goods.

Assembly Drawings: Provide 2D assembly drawings that show how various parts fit together. This includes exploded views, parts lists, and assembly instructions.

Examples: Assembly of mechanical devices like pumps, motors, or machine tools.

Manufacturing Drawings: Prepare 2D drawings for fabrication, including detailed specifications for processes like welding, machining, casting, or sheet metal fabrication.

Examples: Fabricated frames, metal brackets, or chassis.

Piping and Plumbing Diagrams: Create 2D piping layout drawings for mechanical systems such as HVAC, water, and gas piping systems in buildings or industrial plants.

Examples: Plumbing systems, HVAC ducting, or industrial piping layouts.

Tolerancing and GD&T (Geometric Dimensioning and Tolerancing): Develop tolerances using GD&T in 2D to communicate design intents more accurately for complex mechanical components.

Examples: High-precision parts for the aerospace or automotive industry.

Production Drawings: Offer production-ready drawings for parts that can be directly handed off to the manufacturing floor for production, ensuring no errors in the process.

Electrical Engineering:

Wiring Diagrams: Produce 2D electrical schematics and wiring diagrams to show how electrical circuits and systems should be wired, including symbols and components.

Examples: Electrical circuits for industrial control panels, home automation systems, or electrical vehicles.

Circuit Layouts: Provide circuit design drawings that detail the layout and interconnection of electrical components like resistors, capacitors, and integrated circuits.

Examples: Circuit layouts for power supplies, motor controls, and sensors.

Panel Layouts: Design 2D layouts for electrical control panels, including the arrangement of electrical components such as circuit breakers, switches, and relays.

Examples: Electrical panel designs for factories, power plants, or industrial machinery.

Schematic Diagrams: Create schematic diagrams that show electrical components and their interconnections in simplified form, focusing on the flow of electricity.

Examples: Low voltage wiring for lighting, HVAC systems, or control systems.

Power Distribution Schematics: Provide power distribution diagrams showing how electricity is distributed across a facility or building, ensuring the electrical system functions properly.

Examples: Power distribution for commercial buildings, factories, or renewable energy systems.

2. 3D Simulation Services (Mechanical and Electrical Engineering):

3D simulations help visualize designs in a 3D environment, allowing for better understanding of the product’s behavior, performance, and potential issues before physical prototypes are created.

Mechanical Engineering:

3D Modeling and Visualization: Create 3D models of mechanical components and assemblies to visualize and interact with the design before it is manufactured. These models can be used for presentations, marketing, and design validation.

Examples: Prototypes for consumer electronics, automotive parts, or industrial equipment.

Finite Element Analysis (FEA): Offer FEA simulations to analyze how parts or assemblies will perform under various conditions (e.g., stress, temperature, or pressure). This allows you to predict failure points and optimize the design.

Examples: Structural components of machinery, aerospace components, or automotive parts.

Thermal and Fluid Dynamics Simulation (CFD): Provide Computational Fluid Dynamics (CFD) simulations to analyze airflow, heat transfer, and fluid behavior in mechanical systems such as engines, HVAC systems, and pipelines.

Examples: Thermal management of electronics, heat exchangers, or ventilation systems.

Kinematic and Dynamic Analysis: Perform motion analysis to study how parts of a mechanism move, their interactions, and their response to forces.

Examples: Robotics, automotive suspension systems, or conveyor belts.

Design Optimization: Offer services that optimize 3D models to ensure minimal material usage while maintaining performance, strength, and cost-effectiveness.

Examples: Weight reduction for aerospace components or automotive parts.

Assembly Simulation: Use 3D simulations to test how mechanical assemblies will come together during manufacturing or assembly processes, ensuring ease of assembly and no interferences.

Examples: Complex machinery, automotive assemblies, or consumer products.

Prototyping and Testing: Create virtual prototypes using 3D simulations to test how the design will perform under real-world conditions (e.g., durability, temperature, or pressure).

Electrical Engineering:

Circuit Simulation: Perform 3D circuit simulations to predict electrical behavior, optimize designs, and test circuit performance before actual hardware is built. This includes testing for voltage, current, and power efficiency.

Examples: Power supply circuits, motor controllers, or signal processing circuits.

PCB (Printed Circuit Board) Design & Simulation: Offer PCB simulation to ensure that the layout of electrical components is optimal and that the board will function correctly. This can include thermal, electrical, and signal integrity analysis.

Examples: PCB designs for consumer electronics, medical devices, or automotive systems.

Electromagnetic Simulation: Provide electromagnetic field simulations to analyze the behavior of electric and magnetic fields in electrical systems, helping to design efficient and safe components.

Examples: Antenna design, motor coil design, or wireless charging systems.

Power System Simulation: Simulate the behavior of electrical power systems, such as grids or battery systems, to predict performance, load capacity, and fault analysis.

Examples: Power grid optimization, renewable energy systems, or backup power systems.

Motor and Generator Simulation: Simulate the behavior of electric motors and generators, optimizing their design for efficiency, power output, and performance.

Examples: Electric vehicle motors, industrial machines, or renewable energy generators.

Lighting Design and Simulation: Provide 3D lighting simulations to optimize the placement, intensity, and energy efficiency of lighting systems in various settings.

Examples: Building lighting design, streetlights, or industrial lighting.

3. Combined Services for Both Mechanical and Electrical Engineering:

Product Development:

Collaborative Product Design: Offer integrated design services where mechanical and electrical systems are designed together. This can include designing physical components and electrical systems in parallel to ensure compatibility and integration.

Examples: Consumer electronics (smartphones, laptops), automated machinery, or smart devices.

System Integration and Optimization: Help clients integrate mechanical and electrical subsystems into a cohesive final product. Simulate the interaction between mechanical systems (e.g., motors, actuators) and electrical systems (e.g., sensors, controllers) to optimize overall product performance.

Prototyping and Testing:

Virtual Prototyping: Use 3D modeling and simulations to create virtual prototypes that can undergo testing and validation before physical prototypes are built. This saves time and money by identifying design flaws early.

Functional Testing in Simulations: Use simulation tools to test and validate both mechanical and electrical functions in a virtual environment, ensuring that everything works together before moving to production.

Training and Support:

Simulation Training: Offer training services to clients or teams on how to use 3D simulation tools, enabling them to conduct their own analysis and tests for mechanical and electrical designs.

Support for Standards and Compliance: Provide support and ensure that designs meet industry standards, codes, and regulations for mechanical and electrical engineering systems, including compliance with safety, environmental, and energy-efficiency guidelines.

[ Retract  ]

]