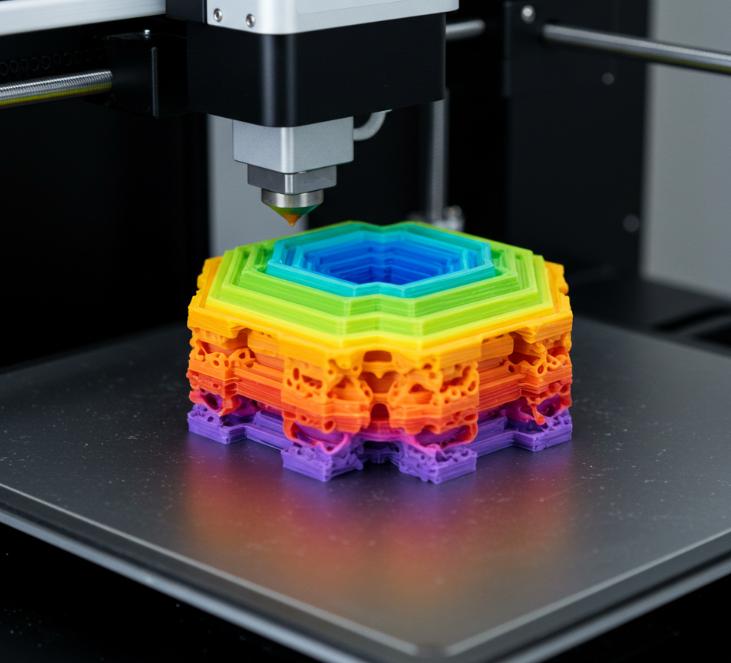

PolyJet 3D printing is an advanced additive manufacturing technology that uses inkjet-style print heads to jet layers of liquid photopolymer onto a build platform. The liquid is immediately cured using UV light, creating solid layers. This process allows for the creation of highly detailed parts with smooth surfaces and the ability to use multiple materials or colors in a single print. PolyJet is ideal for applications that require fine details, multi-material capabilities, and prototypes that closely mimic the final product in terms of texture, color, and flexibility.

As a platform to provide services for PolyJet 3D printing, we offer a variety of services catering to industries such as automotive, medical, aerospace, consumer products, consumer electronics, and design studios. Below are some key services you can request:

1.Prototyping and Rapid Prototyping

High-Precision Prototyping: Offer rapid prototyping with high accuracy and detail for parts and components that need to closely resemble the final product. PolyJet's precision allows for prototypes with fine details and smooth surfaces, ideal for design evaluations and functional testing.

Multi-Material Prototypes: Provide multi-material prototyping services, where different materials can be combined in a single part, offering the ability to simulate varying textures, flexibility, and rigidity in one print. This is useful for functional prototypes that require mixed material properties.

Color Prototypes: Provide multi-color prototypes where various colors can be applied simultaneously. This is ideal for showcasing designs, products, or parts that need to be visually appealing or require distinct color features, such as logos, buttons, or branding.

2. Multi-Material and Multi-Color Parts

Multi-Material Parts: Offer multi-material parts using PolyJet’s capability to combine rigid and flexible materials in one build. This is useful for producing parts that need varying levels of hardness or flexibility in different areas of the same component.

Full-Color Parts: Provide full-color parts for prototypes, models, and end-use products. PolyJet’s ability to print in a wide range of colors allows for high-quality visual prototypes, useful in industries like consumer electronics, toys, and medical devices.

Overmolding and Composite Parts: Offer overmolding services where rigid and flexible materials are combined for parts that mimic the process of traditional overmolding, such as grips, buttons, or other ergonomic features.

3. Functional Prototyping for Testing and Validation

Functional Testing Models: Provide functional testing models that closely simulate the look, feel, and function of the final product. PolyJet allows for the creation of prototypes that can be tested for fit, ergonomics, and performance in early design stages.

User Testing and Ergonomics: Offer user testing prototypes where parts are designed to evaluate ergonomics, user interfaces, or physical interaction with the product, such as handles, interfaces, or wearable devices.

Engineering Models: Provide engineering models that are not only visual but also functional, incorporating necessary mechanical and functional features to simulate real-world use.

4. Medical Device Prototyping and Applications

Medical Device Prototypes: Offer medical device prototypes, including components such as surgical tools, implants, and diagnostic devices. PolyJet’s high resolution allows for the creation of detailed and accurate models suitable for testing and regulatory approvals.

Anatomical Models: Provide patient-specific anatomical models for use in medical planning, education, and surgery. PolyJet can produce highly detailed models from medical imaging data (CT scans or MRIs) to aid in pre-surgical planning and patient communication.

Biocompatible Prototypes: Offer biocompatible prototypes made from materials suitable for medical applications, ensuring prototypes meet regulatory standards for functionality and safety.

5. Consumer Product Development

Product Design Prototyping: Provide consumer product design prototyping for industries like toys, home appliances, wearables, and gadgets. PolyJet allows for the creation of highly detailed, accurate, and visually appealing prototypes for consumer products.

User Interface Models: Offer user interface (UI) prototypes to help visualize and test products with buttons, touchscreens, or display components.

Flexible Parts: Create flexible parts for products that need to simulate the feel of soft-touch materials, such as wearable bands, buttons, or grips, by combining rigid and flexible materials in one print.

6. Educational and Presentation Models

Architectural Models: Provide architectural models that demonstrate complex designs, layouts, or structures for educational purposes, real estate, or presentation to clients. PolyJet’s ability to produce highly detailed and visually accurate models makes it ideal for architectural firms, museums, or exhibitions.

Prototype Demonstrations: Offer demonstration models for products, exhibits, or trade shows that need to showcase a functional or visual aspect. PolyJet allows for models with high detail and smooth surfaces, which is particularly useful in industry-specific presentations.

7. End-Use Parts and Low-Volume Manufacturing

Low-Volume Production: Offer low-volume production of parts and components that are suited for smaller quantities, such as customized products, replacement parts, or limited-edition designs. PolyJet can produce high-quality parts for short production runs.

Functional End-Use Parts: Provide end-use parts that are durable and functional for industries such as consumer electronics, automotive, and industrial applications. PolyJet is capable of producing parts with excellent mechanical properties and fine detail.

Custom Consumer Goods: Offer custom consumer goods like customized phone cases, gadgets, and home decor items. PolyJet's multi-material and color capabilities are ideal for personalization and customization.

8. Tooling and Manufacturing Aids

Custom Jigs, Fixtures, and Tools: Provide custom tooling such as jigs, fixtures, and assembly aids for manufacturers. PolyJet’s ability to create detailed, functional parts can support various stages of the manufacturing process.

Production Aids: Offer production aids for assembly lines, such as part holders, guides, and templates that help streamline manufacturing or assembly tasks.

9. Fine Detail and Complex Geometry Applications

Detailed Components: Offer the ability to create parts with fine details and intricate features that would be difficult to manufacture with traditional methods, such as small or complex internal structures.

Complex Geometries: Provide parts with complex geometries, including parts with undercuts, thin walls, and internal voids. PolyJet can create parts with fine features, such as highly detailed textures or patterns, which are crucial for product development in various industries.

10. PolyJet 3D Printing for Aerospace and Automotive Applications

Aerospace Prototypes: Offer aerospace prototypes for components such as brackets, panels, or housings. PolyJet can produce high-precision parts with the required strength and performance characteristics for the aerospace sector.

Automotive Parts and Prototypes: Provide automotive prototypes for parts such as dashboards, exterior components, or functional prototypes. PolyJet’s fine resolution and multi-material capabilities make it suitable for automotive testing and design evaluations.

11. Fashion, Jewelry, and Art

Jewelry Prototyping: Offer jewelry prototyping services, including rings, bracelets, and other accessories. PolyJet can produce high-precision prototypes with intricate designs and fine details that match the aesthetic requirements of the jewelry industry.

Fashion Accessories: Provide prototyping for fashion accessories, including custom pieces like belts, handbags, buttons, and clothing embellishments that require complex geometry and fine detail.

Art and Sculpture Models: Offer art models or sculptures for artists, designers, and museums. PolyJet can create detailed, high-quality models for art installations, prototype sculptures, or replicas.

12. Design for Additive Manufacturing (DfAM) Consulting

DfAM Consulting: Offer Design for Additive Manufacturing (DfAM) services to help clients optimize their designs for PolyJet printing. This includes advice on minimizing material usage, improving functionality, and designing parts for easier printing and better performance.

Topology Optimization: Provide topology optimization services for clients looking to reduce material usage and increase part strength and efficiency.

PolyJet 3D printing is an advanced additive manufacturing technology that uses inkjet-style print heads to jet layers of liquid photopolymer onto a build platform. The liquid is immediately cured using UV light, creating solid layers. This process allows for the creation of highly detailed parts with smooth surfaces and the ability to use multiple materials or colors in a single print. PolyJet is ideal for applications that require fine details, multi-material capabilities, and prototypes that closely mimic the final product in terms of texture, color, and flexibility.

As a platform to provide services for PolyJet 3D printing, we offer a variety of services catering to industries such as automotive, medical, aerospace, consumer products, consumer electronics, and design studios. Below are some key services you can request:

1.Prototyping and Rapid Prototyping

High-Precision Prototyping: Offer rapid prototyping with high accuracy and detail for parts and components that need to closely resemble the final product. PolyJet's precision allows for prototypes with fine details and smooth surfaces, ideal for design evaluations and functional testing.

Multi-Material Prototypes: Provide multi-material prototyping services, where different materials can be combined in a single part, offering the ability to simulate varying textures, flexibility, and rigidity in one print. This is useful for functional prototypes that require mixed material properties.

Color Prototypes: Provide multi-color prototypes where various colors can be applied simultaneously. This is ideal for showcasing designs, products, or parts that need to be visually appealing or require distinct color features, such as logos, buttons, or branding.

2. Multi-Material and Multi-Color Parts

Multi-Material Parts: Offer multi-material parts using PolyJet’s capability to combine rigid and flexible materials in one build. This is useful for producing parts that need varying levels of hardness or flexibility in different areas of the same component.

Full-Color Parts: Provide full-color parts for prototypes, models, and end-use products. PolyJet’s ability to print in a wide range of colors allows for high-quality visual prototypes, useful in industries like consumer electronics, toys, and medical devices.

Overmolding and Composite Parts: Offer overmolding services where rigid and flexible materials are combined for parts that mimic the process of traditional overmolding, such as grips, buttons, or other ergonomic features.

3. Functional Prototyping for Testing and Validation

Functional Testing Models: Provide functional testing models that closely simulate the look, feel, and function of the final product. PolyJet allows for the creation of prototypes that can be tested for fit, ergonomics, and performance in early design stages.

User Testing and Ergonomics: Offer user testing prototypes where parts are designed to evaluate ergonomics, user interfaces, or physical interaction with the product, such as handles, interfaces, or wearable devices.

Engineering Models: Provide engineering models that are not only visual but also functional, incorporating necessary mechanical and functional features to simulate real-world use.

4. Medical Device Prototyping and Applications

Medical Device Prototypes: Offer medical device prototypes, including components such as surgical tools, implants, and diagnostic devices. PolyJet’s high resolution allows for the creation of detailed and accurate models suitable for testing and regulatory approvals.

Anatomical Models: Provide patient-specific anatomical models for use in medical planning, education, and surgery. PolyJet can produce highly detailed models from medical imaging data (CT scans or MRIs) to aid in pre-surgical planning and patient communication.

Biocompatible Prototypes: Offer biocompatible prototypes made from materials suitable for medical applications, ensuring prototypes meet regulatory standards for functionality and safety.

5. Consumer Product Development

Product Design Prototyping: Provide consumer product design prototyping for industries like toys, home appliances, wearables, and gadgets. PolyJet allows for the creation of highly detailed, accurate, and visually appealing prototypes for consumer products.

User Interface Models: Offer user interface (UI) prototypes to help visualize and test products with buttons, touchscreens, or display components.

Flexible Parts: Create flexible parts for products that need to simulate the feel of soft-touch materials, such as wearable bands, buttons, or grips, by combining rigid and flexible materials in one print.

6. Educational and Presentation Models

Architectural Models: Provide architectural models that demonstrate complex designs, layouts, or structures for educational purposes, real estate, or presentation to clients. PolyJet’s ability to produce highly detailed and visually accurate models makes it ideal for architectural firms, museums, or exhibitions.

Prototype Demonstrations: Offer demonstration models for products, exhibits, or trade shows that need to showcase a functional or visual aspect. PolyJet allows for models with high detail and smooth surfaces, which is particularly useful in industry-specific presentations.

7. End-Use Parts and Low-Volume Manufacturing

Low-Volume Production: Offer low-volume production of parts and components that are suited for smaller quantities, such as customized products, replacement parts, or limited-edition designs. PolyJet can produce high-quality parts for short production runs.

Functional End-Use Parts: Provide end-use parts that are durable and functional for industries such as consumer electronics, automotive, and industrial applications. PolyJet is capable of producing parts with excellent mechanical properties and fine detail.

Custom Consumer Goods: Offer custom consumer goods like customized phone cases, gadgets, and home decor items. PolyJet's multi-material and color capabilities are ideal for personalization and customization.

8. Tooling and Manufacturing Aids

Custom Jigs, Fixtures, and Tools: Provide custom tooling such as jigs, fixtures, and assembly aids for manufacturers. PolyJet’s ability to create detailed, functional parts can support various stages of the manufacturing process.

Production Aids: Offer production aids for assembly lines, such as part holders, guides, and templates that help streamline manufacturing or assembly tasks.

9. Fine Detail and Complex Geometry Applications

Detailed Components: Offer the ability to create parts with fine details and intricate features that would be difficult to manufacture with traditional methods, such as small or complex internal structures.

Complex Geometries: Provide parts with complex geometries, including parts with undercuts, thin walls, and internal voids. PolyJet can create parts with fine features, such as highly detailed textures or patterns, which are crucial for product development in various industries.

10. PolyJet 3D Printing for Aerospace and Automotive Applications

Aerospace Prototypes: Offer aerospace prototypes for components such as brackets, panels, or housings. PolyJet can produce high-precision parts with the required strength and performance characteristics for the aerospace sector.

Automotive Parts and Prototypes: Provide automotive prototypes for parts such as dashboards, exterior components, or functional prototypes. PolyJet’s fine resolution and multi-material capabilities make it suitable for automotive testing and design evaluations.

11. Fashion, Jewelry, and Art

Jewelry Prototyping: Offer jewelry prototyping services, including rings, bracelets, and other accessories. PolyJet can produce high-precision prototypes with intricate designs and fine details that match the aesthetic requirements of the jewelry industry.

Fashion Accessories: Provide prototyping for fashion accessories, including custom pieces like belts, handbags, buttons, and clothing embellishments that require complex geometry and fine detail.

Art and Sculpture Models: Offer art models or sculptures for artists, designers, and museums. PolyJet can create detailed, high-quality models for art installations, prototype sculptures, or replicas.

12. Design for Additive Manufacturing (DfAM) Consulting

DfAM Consulting: Offer Design for Additive Manufacturing (DfAM) services to help clients optimize their designs for PolyJet printing. This includes advice on minimizing material usage, improving functionality, and designing parts for easier printing and better performance.

Topology Optimization: Provide topology optimization services for clients looking to reduce material usage and increase part strength and efficiency.

[ Retract  ]

]