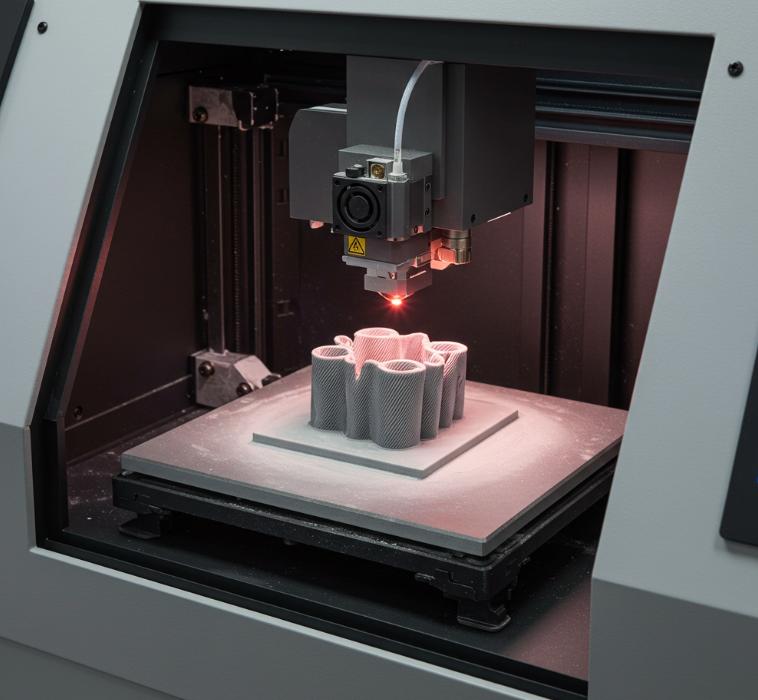

Selective Laser Sintering (SLS) is an advanced 3D printing technology that uses a high-powered laser to sinter (fuse) powdered material, typically nylon, polyamide, or metal powders, into solid structures. SLS offers high precision, functional parts with excellent mechanical properties, making it ideal for applications requiring durability, strength, and complexity. This technology is often used in industries like automotive, aerospace, medical, consumer goods, and industrial manufacturing.

As a platform to provide services for Selective Laser Sintering (SLS), we offer a wide range of services tailored to different industries and applications. Below are the services you can request:

1.Prototyping and Rapid Prototyping

Functional Prototypes: Offer functional prototypes for product design, testing, and validation. SLS allows for the creation of strong, durable parts that closely mimic the final product's performance and appearance.

Complex Geometries: Provide the ability to produce prototypes with complex geometries, including internal structures, channels, or parts that would be difficult or impossible to create using traditional manufacturing methods.

Rapid Prototyping: Deliver rapid prototyping services with quick turnaround times, allowing clients to test and iterate on designs before mass production. SLS can rapidly produce parts without the need for tooling.

2. Low-to-Medium Volume Production

Low-Volume Manufacturing: Offer low-volume production runs, where SLS 3D printing is ideal for small to medium quantities of functional parts. This is particularly useful for products that do not justify the high cost of injection molding or traditional tooling.

On-Demand Manufacturing: Provide on-demand manufacturing services, where clients can order parts as needed, allowing for flexible production without the need to hold large inventories.

Spare Parts Production: Offer on-demand spare parts manufacturing for industries like automotive, machinery, and industrial equipment. SLS enables the production of spare parts without the need for traditional molds or tooling.

3. Custom Parts and Components

Custom Functional Components: Provide custom components for specific applications such as brackets, enclosures, gears, and mechanical parts. SLS can create parts with excellent mechanical properties, making it suitable for high-stress and high-performance applications.

Complex, Intricate Designs: Offer highly intricate custom designs that are difficult to manufacture with traditional methods, including parts with internal cavities, intricate meshes, or lattice structures.

4. Material Selection and Customization

Material Expertise: Offer material consulting services to help clients choose the right materials for their needs. SLS supports a variety of materials, including nylon (PA 12, PA 11), glass-filled nylon, flexible materials, and metal powders.

Custom Materials: Work with clients to develop custom materials or tailored blends to meet specific performance requirements such as strength, flexibility, high-temperature resistance, or chemical resistance.

5. Post-Processing and Finishing Services

Cleaning and Powder Removal: Offer post-processing services such as powder removal (cleaning excess material from parts) to ensure parts are ready for use.

Surface Finishing: Provide surface finishing services such as sanding, polishing, or texturing to improve the aesthetic quality of parts, making them more suitable for consumer-facing products or applications where appearance matters.

Coloring and Coating: Offer coloring and coating services, including custom colors or protective coatings, to enhance the look, durability, and performance of the printed parts.

Heat Treatment: Provide heat treatment options to further enhance the mechanical properties of parts, such as increasing strength or improving heat resistance.

6. SLS 3D Printing for Automotive Applications

Automotive Prototypes: Offer automotive prototypes for parts such as dashboards, interior components, brackets, or housings. SLS can create lightweight, durable components for testing and design evaluation.

End-Use Automotive Parts: Provide end-use automotive parts, such as custom brackets, mounts, or functional components for vehicles, ensuring they meet strength, weight, and durability requirements.

Tooling and Fixtures: Offer custom tooling, jigs, and fixtures for assembly lines, providing automotive manufacturers with parts that support their production processes.

7. SLS 3D Printing for Aerospace Applications

Aerospace Components: Provide aerospace-grade parts for applications such as brackets, housings, panels, and other components that need to meet stringent performance and weight requirements.

Lightweight Structural Parts: Offer lightweight structural parts for aerospace applications that reduce the overall weight of aircraft and spacecraft, improving fuel efficiency and performance.

Aerospace Prototyping: Provide prototypes for aerospace components, allowing engineers to test part fit, performance, and manufacturability before full-scale production.

8. SLS 3D Printing for Medical and Healthcare Applications

Medical Device Prototyping: Offer medical device prototyping, including surgical instruments, implants, or diagnostic devices. SLS can create parts with high precision and functional properties that mimic the final product.

Custom Prosthetics and Implants: Provide custom prosthetics and implants tailored to individual patients, ensuring perfect fit and optimal performance. SLS is ideal for creating patient-specific parts for orthopedic applications.

Anatomical Models: Offer 3D-printed anatomical models for medical professionals to use in surgery planning, patient communication, and education.

9. SLS 3D Printing for Consumer Goods

Consumer Product Prototyping: Provide consumer product prototyping for items like electronics housings, wearables, or home appliances. SLS can create functional, durable prototypes that are tested for form and fit before production.

Custom Consumer Products: Offer custom consumer products such as bespoke phone cases, tech accessories, or custom tools. SLS allows for high levels of customization, enabling clients to create unique and functional products.

Lightweight Components: Provide lightweight components for consumer products where weight reduction is important, such as fitness trackers, smart devices, or personal accessories.

10. SLS 3D Printing for Industrial Applications

Industrial Prototypes: Offer industrial prototypes for equipment, machinery, and components that require high strength, durability, and precision. SLS is well-suited for creating functional prototypes that undergo rigorous testing.

Custom Parts and Tools: Provide custom industrial tools such as assembly jigs, tooling, and fixtures that support the manufacturing process or maintenance activities in industries like oil & gas, machinery, and electronics.

End-Use Industrial Parts: Provide end-use industrial parts such as brackets, mounts, housings, and functional components that are durable and reliable for production environments.

11. SLS 3D Printing for Electronics

Electronic Enclosures: Offer custom enclosures for electronics, providing parts with excellent durability and protection for sensitive internal components.

Complex Internal Structures: Provide parts with internal channels, cabling pathways, or integrated features that can’t be produced using traditional manufacturing methods.

12. SLS for Design and Manufacturing Consultations

Design for Additive Manufacturing (DfAM): Offer DfAM consulting services to optimize designs for 3D printing. Help clients reduce material waste, improve part functionality, and leverage the full potential of SLS technology.

Topology Optimization: Provide topology optimization services to create parts that are strong yet lightweight, improving material efficiency and overall performance.

Reverse Engineering: Offer reverse engineering services where you can create 3D models from existing parts, enabling design improvements and facilitating manufacturing using SLS.

13. Material Development and Customization

Material Research: Help clients explore the use of new materials for SLS printing. Materials like metal-filled nylon, flexible resins, or heat-resistant plastics can be developed for specific applications.

Specialized Material Solutions: Provide custom materials for applications that require unique properties, such as flame-retardant materials, biocompatible resins, or high-strength composites.

Selective Laser Sintering (SLS) is an advanced 3D printing technology that uses a high-powered laser to sinter (fuse) powdered material, typically nylon, polyamide, or metal powders, into solid structures. SLS offers high precision, functional parts with excellent mechanical properties, making it ideal for applications requiring durability, strength, and complexity. This technology is often used in industries like automotive, aerospace, medical, consumer goods, and industrial manufacturing.

As a platform to provide services for Selective Laser Sintering (SLS), we offer a wide range of services tailored to different industries and applications. Below are the services you can request:

1.Prototyping and Rapid Prototyping

Functional Prototypes: Offer functional prototypes for product design, testing, and validation. SLS allows for the creation of strong, durable parts that closely mimic the final product's performance and appearance.

Complex Geometries: Provide the ability to produce prototypes with complex geometries, including internal structures, channels, or parts that would be difficult or impossible to create using traditional manufacturing methods.

Rapid Prototyping: Deliver rapid prototyping services with quick turnaround times, allowing clients to test and iterate on designs before mass production. SLS can rapidly produce parts without the need for tooling.

2. Low-to-Medium Volume Production

Low-Volume Manufacturing: Offer low-volume production runs, where SLS 3D printing is ideal for small to medium quantities of functional parts. This is particularly useful for products that do not justify the high cost of injection molding or traditional tooling.

On-Demand Manufacturing: Provide on-demand manufacturing services, where clients can order parts as needed, allowing for flexible production without the need to hold large inventories.

Spare Parts Production: Offer on-demand spare parts manufacturing for industries like automotive, machinery, and industrial equipment. SLS enables the production of spare parts without the need for traditional molds or tooling.

3. Custom Parts and Components

Custom Functional Components: Provide custom components for specific applications such as brackets, enclosures, gears, and mechanical parts. SLS can create parts with excellent mechanical properties, making it suitable for high-stress and high-performance applications.

Complex, Intricate Designs: Offer highly intricate custom designs that are difficult to manufacture with traditional methods, including parts with internal cavities, intricate meshes, or lattice structures.

4. Material Selection and Customization

Material Expertise: Offer material consulting services to help clients choose the right materials for their needs. SLS supports a variety of materials, including nylon (PA 12, PA 11), glass-filled nylon, flexible materials, and metal powders.

Custom Materials: Work with clients to develop custom materials or tailored blends to meet specific performance requirements such as strength, flexibility, high-temperature resistance, or chemical resistance.

5. Post-Processing and Finishing Services

Cleaning and Powder Removal: Offer post-processing services such as powder removal (cleaning excess material from parts) to ensure parts are ready for use.

Surface Finishing: Provide surface finishing services such as sanding, polishing, or texturing to improve the aesthetic quality of parts, making them more suitable for consumer-facing products or applications where appearance matters.

Coloring and Coating: Offer coloring and coating services, including custom colors or protective coatings, to enhance the look, durability, and performance of the printed parts.

Heat Treatment: Provide heat treatment options to further enhance the mechanical properties of parts, such as increasing strength or improving heat resistance.

6. SLS 3D Printing for Automotive Applications

Automotive Prototypes: Offer automotive prototypes for parts such as dashboards, interior components, brackets, or housings. SLS can create lightweight, durable components for testing and design evaluation.

End-Use Automotive Parts: Provide end-use automotive parts, such as custom brackets, mounts, or functional components for vehicles, ensuring they meet strength, weight, and durability requirements.

Tooling and Fixtures: Offer custom tooling, jigs, and fixtures for assembly lines, providing automotive manufacturers with parts that support their production processes.

7. SLS 3D Printing for Aerospace Applications

Aerospace Components: Provide aerospace-grade parts for applications such as brackets, housings, panels, and other components that need to meet stringent performance and weight requirements.

Lightweight Structural Parts: Offer lightweight structural parts for aerospace applications that reduce the overall weight of aircraft and spacecraft, improving fuel efficiency and performance.

Aerospace Prototyping: Provide prototypes for aerospace components, allowing engineers to test part fit, performance, and manufacturability before full-scale production.

8. SLS 3D Printing for Medical and Healthcare Applications

Medical Device Prototyping: Offer medical device prototyping, including surgical instruments, implants, or diagnostic devices. SLS can create parts with high precision and functional properties that mimic the final product.

Custom Prosthetics and Implants: Provide custom prosthetics and implants tailored to individual patients, ensuring perfect fit and optimal performance. SLS is ideal for creating patient-specific parts for orthopedic applications.

Anatomical Models: Offer 3D-printed anatomical models for medical professionals to use in surgery planning, patient communication, and education.

9. SLS 3D Printing for Consumer Goods

Consumer Product Prototyping: Provide consumer product prototyping for items like electronics housings, wearables, or home appliances. SLS can create functional, durable prototypes that are tested for form and fit before production.

Custom Consumer Products: Offer custom consumer products such as bespoke phone cases, tech accessories, or custom tools. SLS allows for high levels of customization, enabling clients to create unique and functional products.

Lightweight Components: Provide lightweight components for consumer products where weight reduction is important, such as fitness trackers, smart devices, or personal accessories.

10. SLS 3D Printing for Industrial Applications

Industrial Prototypes: Offer industrial prototypes for equipment, machinery, and components that require high strength, durability, and precision. SLS is well-suited for creating functional prototypes that undergo rigorous testing.

Custom Parts and Tools: Provide custom industrial tools such as assembly jigs, tooling, and fixtures that support the manufacturing process or maintenance activities in industries like oil & gas, machinery, and electronics.

End-Use Industrial Parts: Provide end-use industrial parts such as brackets, mounts, housings, and functional components that are durable and reliable for production environments.

11. SLS 3D Printing for Electronics

Electronic Enclosures: Offer custom enclosures for electronics, providing parts with excellent durability and protection for sensitive internal components.

Complex Internal Structures: Provide parts with internal channels, cabling pathways, or integrated features that can’t be produced using traditional manufacturing methods.

12. SLS for Design and Manufacturing Consultations

Design for Additive Manufacturing (DfAM): Offer DfAM consulting services to optimize designs for 3D printing. Help clients reduce material waste, improve part functionality, and leverage the full potential of SLS technology.

Topology Optimization: Provide topology optimization services to create parts that are strong yet lightweight, improving material efficiency and overall performance.

Reverse Engineering: Offer reverse engineering services where you can create 3D models from existing parts, enabling design improvements and facilitating manufacturing using SLS.

13. Material Development and Customization

Material Research: Help clients explore the use of new materials for SLS printing. Materials like metal-filled nylon, flexible resins, or heat-resistant plastics can be developed for specific applications.

Specialized Material Solutions: Provide custom materials for applications that require unique properties, such as flame-retardant materials, biocompatible resins, or high-strength composites.

[ Retract  ]

]