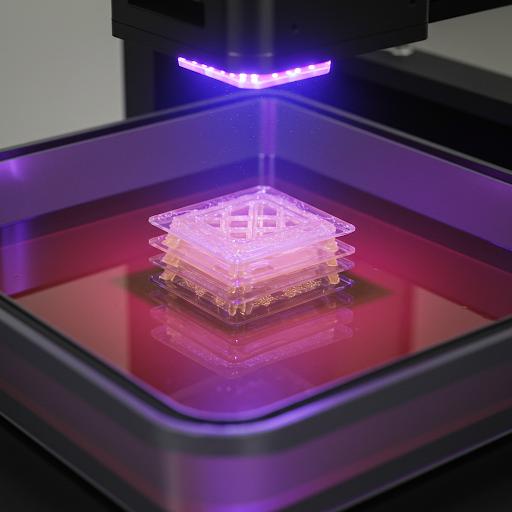

Advanced Photopolymers are specialized materials used in 3D printing and additive manufacturing processes, particularly in technologies like SLA (Stereolithography), DLP (Digital Light Processing), and PolyJet. These materials are designed to cure and solidify when exposed to light, typically ultraviolet (UV), enabling the production of high-resolution, high-precision parts with unique mechanical, optical, and thermal properties. Advanced photopolymers offer benefits such as high strength, flexibility, transparency, biocompatibility, and resistance to high temperatures, making them ideal for a wide range of applications in industries like medical, aerospace, automotive, consumer goods, electronics, and jewelry.

As a platform to provide services for Advanced Photopolymers, you can request the following services:

1.Prototyping and Rapid Prototyping

High-Resolution Prototyping: Offer high-resolution prototyping with advanced photopolymers for parts and components that require intricate details and smooth finishes. This is particularly useful for applications where fine features and high surface quality are critical, such as consumer electronics, jewelry, and precision components.

Functional Prototypes: Provide functional prototypes that closely simulate the final product's material properties and performance. Advanced photopolymers can be used to create prototypes with mechanical strength, flexibility, or rigidity depending on the client's needs.

Low-Volume Production Prototypes: Offer low-volume production prototypes where clients need to produce small batches of parts for design verification or testing before moving into full-scale production.

2. Medical Applications

Medical Device Prototyping: Offer medical device prototypes using biocompatible advanced photopolymers, ideal for creating prototypes of surgical instruments, implants, and diagnostic tools that require both high precision and safety standards.

Anatomical Models: Provide patient-specific anatomical models derived from medical imaging (CT scans, MRIs) for use in medical training, pre-surgical planning, and patient communication. These models can help surgeons visualize complex anatomical features and improve the quality of medical interventions.

Biocompatible Prototypes: Offer biocompatible prototypes for implants, prosthetics, and medical tools. These photopolymers meet regulatory standards for medical devices, providing prototypes that are safe for use in patient care and medical research.

3. Consumer Goods and Product Development

Custom Consumer Products: Offer custom consumer product prototyping for industries like fashion, wearables, and personal gadgets. Advanced photopolymers allow for high-quality, intricate designs with detailed features such as buttons, logos, and decorative elements.

Packaging Prototypes: Provide packaging design prototyping with photopolymers to create intricate, high-quality models for packaging testing, including snap-fit closures, labels, and detailed product enclosures.

Cosmetic Prototypes: Offer cosmetic product prototypes such as perfume bottles, makeup containers, and other high-end consumer goods where appearance, texture, and branding are important.

4. Jewelry Design and Prototyping

Jewelry Prototypes: Provide high-precision jewelry prototypes using advanced photopolymers. These materials can create intricate, detailed models for rings, necklaces, and other accessories, allowing jewelers to visualize and refine designs before production.

Custom Jewelry: Offer custom jewelry creation for clients looking for unique, one-of-a-kind pieces. Advanced photopolymers enable the production of complex designs with fine details and smooth surfaces.

Casting Patterns: Use photopolymers to create casting patterns for lost-wax casting in the jewelry industry. These prototypes can withstand high temperatures, allowing jewelers to use them as patterns for metal casting.

5. Automotive and Aerospace Applications

Automotive Prototyping: Offer automotive prototypes for components such as dashboards, handles, or exterior parts. Advanced photopolymers can be used to create durable, high-quality parts that simulate the final product's appearance and function.

Aerospace Components: Provide aerospace prototypes for parts such as brackets, housings, or fittings. Photopolymers with high temperature resistance and strength are ideal for aerospace applications that demand precision and durability.

Custom Tools and Fixtures: Offer the creation of custom automotive and aerospace tools, jigs, and fixtures for the manufacturing process, such as components that assist in assembly, testing, or part alignment.

6. Electronics and Electrical Components

Enclosures and Housings: Offer electronic enclosures for consumer electronics, including custom casings for devices such as smartphones, tablets, and wearables. Advanced photopolymers are ideal for producing strong, detailed, and lightweight enclosures.

Connectors and Mounts: Provide electronic connectors, mounts, and other small electronic components that require high precision and fine details. Photopolymers can be used to create intricate, high-performance parts that meet the exact needs of the electrical industry.

Thermal Management Parts: Offer thermal management parts such as heat sinks and insulation components using advanced photopolymers that can withstand high temperatures while maintaining structural integrity.

7. Architectural and Design Models

Architectural Models: Offer highly detailed architectural models for real estate developers, architects, and urban planners. Photopolymers provide the ability to create models with intricate details, smooth finishes, and multi-material components.

Interior Design Prototypes: Provide interior design models for furniture, lighting, and decor items. Advanced photopolymers enable the production of complex and artistic designs for interior spaces.

Scale Models: Provide scale models for cities, buildings, or exhibitions, allowing for accurate visual representations of large-scale projects.

8. Custom Parts and Industrial Applications

Functional Industrial Parts: Provide functional industrial parts such as gears, brackets, and mechanical components that require both durability and precision. Advanced photopolymers offer the right balance of strength and flexibility for many industrial applications.

Custom Manufacturing Aids: Offer custom manufacturing aids, such as jigs, fixtures, and tooling that help streamline the manufacturing process or improve product assembly.

9. Rapid Tooling and Low-Volume Production

Rapid Tooling: Offer rapid tooling services where advanced photopolymers are used to produce tools, molds, or inserts that can be used for short-run manufacturing or prototyping. This is particularly useful for low-volume production before investing in expensive, traditional tooling.

Low-Volume Production Parts: Provide low-volume production services for parts that require precision, high-quality finishes, and functional properties that are too complex to create with traditional methods.

10. Advanced Material Consulting

Material Selection and Testing: Offer material consulting services to help clients select the right photopolymer for their specific application. With the wide variety of advanced photopolymers available, you can guide clients in choosing materials that offer the best balance of strength, flexibility, transparency, or heat resistance.

Custom Photopolymer Development: Work with clients to develop custom photopolymers with unique properties, such as higher durability, specific color ranges, or resistance to certain chemicals. This can be particularly useful for specialized industries like medical devices or automotive.

11. Post-Processing Services

Cleaning and Support Removal: Offer post-processing services such as the removal of support structures, cleaning, and finishing for parts printed with photopolymer resins.

Surface Finishing: Provide surface finishing services like sanding, polishing, or coating to improve the appearance or mechanical properties of the printed parts.

Painting and Texturing: Offer painting and texturing services to add realistic finishes, such as glossy or matte textures, to parts, enhancing the final look and feel of consumer-facing products.

12. Prototyping for High-Detail Models

Art and Sculptural Prototyping: Offer high-detail art prototyping for artists, designers, and museums who need to create intricate sculptures, models, or designs. Advanced photopolymers allow for the production of highly detailed and visually accurate models.

Museum Replicas: Provide museum-quality replicas of historical artifacts, sculptures, or art pieces, where fine details are critical for preservation and educational purposes.

Advanced Photopolymers are specialized materials used in 3D printing and additive manufacturing processes, particularly in technologies like SLA (Stereolithography), DLP (Digital Light Processing), and PolyJet. These materials are designed to cure and solidify when exposed to light, typically ultraviolet (UV), enabling the production of high-resolution, high-precision parts with unique mechanical, optical, and thermal properties. Advanced photopolymers offer benefits such as high strength, flexibility, transparency, biocompatibility, and resistance to high temperatures, making them ideal for a wide range of applications in industries like medical, aerospace, automotive, consumer goods, electronics, and jewelry.

As a platform to provide services for Advanced Photopolymers, you can request the following services:

1.Prototyping and Rapid Prototyping

High-Resolution Prototyping: Offer high-resolution prototyping with advanced photopolymers for parts and components that require intricate details and smooth finishes. This is particularly useful for applications where fine features and high surface quality are critical, such as consumer electronics, jewelry, and precision components.

Functional Prototypes: Provide functional prototypes that closely simulate the final product's material properties and performance. Advanced photopolymers can be used to create prototypes with mechanical strength, flexibility, or rigidity depending on the client's needs.

Low-Volume Production Prototypes: Offer low-volume production prototypes where clients need to produce small batches of parts for design verification or testing before moving into full-scale production.

2. Medical Applications

Medical Device Prototyping: Offer medical device prototypes using biocompatible advanced photopolymers, ideal for creating prototypes of surgical instruments, implants, and diagnostic tools that require both high precision and safety standards.

Anatomical Models: Provide patient-specific anatomical models derived from medical imaging (CT scans, MRIs) for use in medical training, pre-surgical planning, and patient communication. These models can help surgeons visualize complex anatomical features and improve the quality of medical interventions.

Biocompatible Prototypes: Offer biocompatible prototypes for implants, prosthetics, and medical tools. These photopolymers meet regulatory standards for medical devices, providing prototypes that are safe for use in patient care and medical research.

3. Consumer Goods and Product Development

Custom Consumer Products: Offer custom consumer product prototyping for industries like fashion, wearables, and personal gadgets. Advanced photopolymers allow for high-quality, intricate designs with detailed features such as buttons, logos, and decorative elements.

Packaging Prototypes: Provide packaging design prototyping with photopolymers to create intricate, high-quality models for packaging testing, including snap-fit closures, labels, and detailed product enclosures.

Cosmetic Prototypes: Offer cosmetic product prototypes such as perfume bottles, makeup containers, and other high-end consumer goods where appearance, texture, and branding are important.

4. Jewelry Design and Prototyping

Jewelry Prototypes: Provide high-precision jewelry prototypes using advanced photopolymers. These materials can create intricate, detailed models for rings, necklaces, and other accessories, allowing jewelers to visualize and refine designs before production.

Custom Jewelry: Offer custom jewelry creation for clients looking for unique, one-of-a-kind pieces. Advanced photopolymers enable the production of complex designs with fine details and smooth surfaces.

Casting Patterns: Use photopolymers to create casting patterns for lost-wax casting in the jewelry industry. These prototypes can withstand high temperatures, allowing jewelers to use them as patterns for metal casting.

5. Automotive and Aerospace Applications

Automotive Prototyping: Offer automotive prototypes for components such as dashboards, handles, or exterior parts. Advanced photopolymers can be used to create durable, high-quality parts that simulate the final product's appearance and function.

Aerospace Components: Provide aerospace prototypes for parts such as brackets, housings, or fittings. Photopolymers with high temperature resistance and strength are ideal for aerospace applications that demand precision and durability.

Custom Tools and Fixtures: Offer the creation of custom automotive and aerospace tools, jigs, and fixtures for the manufacturing process, such as components that assist in assembly, testing, or part alignment.

6. Electronics and Electrical Components

Enclosures and Housings: Offer electronic enclosures for consumer electronics, including custom casings for devices such as smartphones, tablets, and wearables. Advanced photopolymers are ideal for producing strong, detailed, and lightweight enclosures.

Connectors and Mounts: Provide electronic connectors, mounts, and other small electronic components that require high precision and fine details. Photopolymers can be used to create intricate, high-performance parts that meet the exact needs of the electrical industry.

Thermal Management Parts: Offer thermal management parts such as heat sinks and insulation components using advanced photopolymers that can withstand high temperatures while maintaining structural integrity.

7. Architectural and Design Models

Architectural Models: Offer highly detailed architectural models for real estate developers, architects, and urban planners. Photopolymers provide the ability to create models with intricate details, smooth finishes, and multi-material components.

Interior Design Prototypes: Provide interior design models for furniture, lighting, and decor items. Advanced photopolymers enable the production of complex and artistic designs for interior spaces.

Scale Models: Provide scale models for cities, buildings, or exhibitions, allowing for accurate visual representations of large-scale projects.

8. Custom Parts and Industrial Applications

Functional Industrial Parts: Provide functional industrial parts such as gears, brackets, and mechanical components that require both durability and precision. Advanced photopolymers offer the right balance of strength and flexibility for many industrial applications.

Custom Manufacturing Aids: Offer custom manufacturing aids, such as jigs, fixtures, and tooling that help streamline the manufacturing process or improve product assembly.

9. Rapid Tooling and Low-Volume Production

Rapid Tooling: Offer rapid tooling services where advanced photopolymers are used to produce tools, molds, or inserts that can be used for short-run manufacturing or prototyping. This is particularly useful for low-volume production before investing in expensive, traditional tooling.

Low-Volume Production Parts: Provide low-volume production services for parts that require precision, high-quality finishes, and functional properties that are too complex to create with traditional methods.

10. Advanced Material Consulting

Material Selection and Testing: Offer material consulting services to help clients select the right photopolymer for their specific application. With the wide variety of advanced photopolymers available, you can guide clients in choosing materials that offer the best balance of strength, flexibility, transparency, or heat resistance.

Custom Photopolymer Development: Work with clients to develop custom photopolymers with unique properties, such as higher durability, specific color ranges, or resistance to certain chemicals. This can be particularly useful for specialized industries like medical devices or automotive.

11. Post-Processing Services

Cleaning and Support Removal: Offer post-processing services such as the removal of support structures, cleaning, and finishing for parts printed with photopolymer resins.

Surface Finishing: Provide surface finishing services like sanding, polishing, or coating to improve the appearance or mechanical properties of the printed parts.

Painting and Texturing: Offer painting and texturing services to add realistic finishes, such as glossy or matte textures, to parts, enhancing the final look and feel of consumer-facing products.

12. Prototyping for High-Detail Models

Art and Sculptural Prototyping: Offer high-detail art prototyping for artists, designers, and museums who need to create intricate sculptures, models, or designs. Advanced photopolymers allow for the production of highly detailed and visually accurate models.

Museum Replicas: Provide museum-quality replicas of historical artifacts, sculptures, or art pieces, where fine details are critical for preservation and educational purposes.

[ Retract  ]

]