Die casting is a metal casting process in which molten metal is injected into a mold cavity under high pressure. This process is used to produce precise, high-quality metal parts quickly and efficiently, making it ideal for industries like automotive, aerospace, electronics, and consumer products. Here’s a comprehensive list of the services you can request about die casting:

1. Die Casting Design and Engineering

Design Consultation: Offer design support for creating die-cast parts, helping customers optimize their designs for cost-efficiency, durability, and manufacturability. This includes considerations for tooling, material selection, and part complexity.

Prototype Development: Provide rapid prototyping services using 3D printing or short-run die casting to help customers test the design and functionality of their parts before full-scale production.

Tooling Design and Manufacturing: Offer custom tooling design and tooling manufacturing for creating molds and dies tailored to specific parts. Provide expertise in designing complex tooling for high-precision casting applications.

Engineering Analysis: Provide simulation and analysis (such as casting simulations, stress testing, and thermal analysis) to identify potential issues in the design, like air pockets, defects, or thin walls that might affect the quality of the cast.

2. Die Casting Process Types

Hot Chamber Die Casting: Offer hot chamber die casting services for non-ferrous metals such as zinc, magnesium, and tin. This process is ideal for high-volume, high-precision applications in industries like automotive and electronics.

Cold Chamber Die Casting: Provide cold chamber die casting for aluminum and copper-based alloys, which require higher temperatures than those used in hot chamber processes. This is typically used for automotive and aerospace components.

Low-Pressure Die Casting: Offer low-pressure die casting for casting parts that require high quality, complex shapes, and thinner walls. This method is often used in industries like automotive for producing lightweight, high-performance parts.

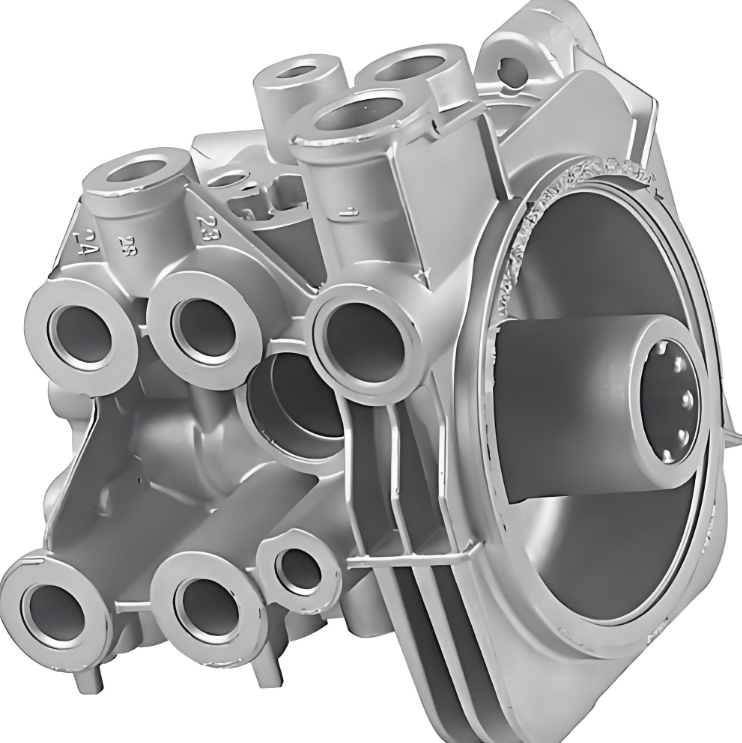

High-Pressure Die Casting: Provide high-pressure die casting services for large, complex parts with fine features and tight tolerances. This is ideal for parts like engine blocks, transmission components, and motor housings.

3. Material Selection and Sourcing

Aluminum Die Casting: Offer aluminum die casting services, which is widely used in industries like automotive, aerospace, and electronics. Aluminum die casting is known for its light weight, excellent thermal conductivity, and corrosion resistance.

Zinc Die Casting: Provide zinc die casting services, commonly used in electrical, consumer goods, and automotive industries. Zinc is ideal for creating complex shapes with tight tolerances due to its excellent fluidity.

Magnesium Die Casting: Offer magnesium die casting for lightweight and high-strength applications, often used in the automotive and electronics sectors where weight is a critical factor.

Copper Alloy Die Casting: Provide copper alloy die casting for parts requiring high strength, thermal conductivity, and electrical conductivity, typically used in electrical connectors, automotive components, and marine applications.

Lead-Free Alloys: Offer lead-free die casting for environmentally-friendly and compliant solutions, especially for industries needing non-toxic materials, such as in food-grade applications or medical devices.

4. Die Casting Production and Manufacturing

Mass Production: Provide high-volume mass production die casting services for parts used in industries like automotive, electronics, and consumer products. This includes batch runs, ensuring consistency and efficiency in large quantities.

Small Batch Production: Offer small batch die casting for industries that need shorter production runs, such as prototypes or limited-edition products.

Complex Shape Casting: Specialize in die casting parts with complex geometries, including thin walls, fine details, and intricate features for industries like aerospace, medical devices, and electronics.

Precision Die Casting: Offer high-precision die casting services to create parts with tight tolerances, such as those used in precision engineering, medical equipment, and electronics.

5. Finishing and Secondary Services

Surface Finishing: Provide post-casting surface finishing services like polishing, deburring, graining, shot blasting, and sandblasting to enhance the aesthetic appearance and functional properties of the die-cast parts.

Machining: Offer machining services like CNC milling, CNC turning, and drilling to add fine details and achieve precise dimensions after the die casting process.

Painting and Coating: Provide painting, powder coating, and electroplating services to add color, improve the appearance, or provide additional corrosion resistance.

Heat Treatment: Offer heat treatment services to improve the mechanical properties of die-cast parts, such as hardness, strength, and fatigue resistance. This may include annealing, quenching, or tempering.

Tapping and Threading: Offer tapping and threading services to add internal and external threads to die-cast parts, which is often required for fasteners or assemblies.

6. Quality Control and Testing

Dimensional Inspection: Provide dimensional inspection services to ensure that die-cast parts meet the required tolerances and specifications, using coordinate measuring machines (CMMs) and optical measurement tools.

Non-Destructive Testing (NDT): Offer NDT services such as X-ray inspection, ultrasonic testing, and die penetrant testing to detect internal defects like voids, porosity, and cracks in die-cast parts.

Mechanical Property Testing: Provide testing services to assess strength, hardness, ductility, and impact resistance of the cast parts, ensuring they meet industry standards and customer specifications.

Porosity Testing: Perform porosity testing to detect air bubbles and voids inside the die-cast parts, which can affect the part's strength and performance.

Thermal Cycling Tests: Offer thermal cycling tests to assess the durability of die-cast parts under extreme temperature fluctuations, often necessary for automotive and aerospace applications.

7. Sustainability and Environmentally Friendly Die Casting

Recycled Materials: Provide die casting services using recycled metals like aluminum and zinc, helping customers achieve sustainability goals while maintaining high-quality standards.

Eco-friendly Die Casting: Implement environmentally friendly practices, such as using non-toxic coatings, low-emission processes, and energy-efficient machinery, to reduce the environmental impact of the die-casting operation.

Zero-Waste Practices: Offer zero-waste die casting services, ensuring that scrap metal and other by-products are properly recycled or repurposed, contributing to a circular economy.

8. Die Casting Tool Maintenance and Repair

Tool Design Optimization: Offer services to improve and optimize casting dies for longer life and better efficiency. This includes redesigning tool components that experience high wear and tear.

Die Repair Services: Provide die repair services to fix issues like cracks, wear, or damage in the die tools to ensure the continued quality of casting.

Tooling Maintenance: Offer routine tooling maintenance services to ensure the longevity and precision of the die-casting tools and maintain consistent part quality throughout the production run.

9. Die Casting for Specific Industries

Automotive Die Casting: Specialize in die casting for automotive parts, including engine components, transmission parts, brackets, and heat exchangers, ensuring durability and performance.

Aerospace Die Casting: Provide die-cast components for the aerospace industry, including aircraft parts, turbine components, and control systems, ensuring lightweight and strong parts that meet aerospace standards.

Medical Device Die Casting: Offer precision die-cast components for medical devices like surgical instruments, prosthetics, implants, and diagnostic equipment, ensuring high-quality, reliable parts.

Electronics Die Casting: Provide die casting for electronic enclosures, connectors, heat sinks, and housing parts for the consumer electronics industry, offering both functional and aesthetic solutions.

Consumer Products: Offer die casting for high-quality consumer goods like appliance parts, decorative items, and hardware components, ensuring design flexibility and performance.

Die casting is a metal casting process in which molten metal is injected into a mold cavity under high pressure. This process is used to produce precise, high-quality metal parts quickly and efficiently, making it ideal for industries like automotive, aerospace, electronics, and consumer products. Here’s a comprehensive list of the services you can request about die casting:

1. Die Casting Design and Engineering

Design Consultation: Offer design support for creating die-cast parts, helping customers optimize their designs for cost-efficiency, durability, and manufacturability. This includes considerations for tooling, material selection, and part complexity.

Prototype Development: Provide rapid prototyping services using 3D printing or short-run die casting to help customers test the design and functionality of their parts before full-scale production.

Tooling Design and Manufacturing: Offer custom tooling design and tooling manufacturing for creating molds and dies tailored to specific parts. Provide expertise in designing complex tooling for high-precision casting applications.

Engineering Analysis: Provide simulation and analysis (such as casting simulations, stress testing, and thermal analysis) to identify potential issues in the design, like air pockets, defects, or thin walls that might affect the quality of the cast.

2. Die Casting Process Types

Hot Chamber Die Casting: Offer hot chamber die casting services for non-ferrous metals such as zinc, magnesium, and tin. This process is ideal for high-volume, high-precision applications in industries like automotive and electronics.

Cold Chamber Die Casting: Provide cold chamber die casting for aluminum and copper-based alloys, which require higher temperatures than those used in hot chamber processes. This is typically used for automotive and aerospace components.

Low-Pressure Die Casting: Offer low-pressure die casting for casting parts that require high quality, complex shapes, and thinner walls. This method is often used in industries like automotive for producing lightweight, high-performance parts.

High-Pressure Die Casting: Provide high-pressure die casting services for large, complex parts with fine features and tight tolerances. This is ideal for parts like engine blocks, transmission components, and motor housings.

3. Material Selection and Sourcing

Aluminum Die Casting: Offer aluminum die casting services, which is widely used in industries like automotive, aerospace, and electronics. Aluminum die casting is known for its light weight, excellent thermal conductivity, and corrosion resistance.

Zinc Die Casting: Provide zinc die casting services, commonly used in electrical, consumer goods, and automotive industries. Zinc is ideal for creating complex shapes with tight tolerances due to its excellent fluidity.

Magnesium Die Casting: Offer magnesium die casting for lightweight and high-strength applications, often used in the automotive and electronics sectors where weight is a critical factor.

Copper Alloy Die Casting: Provide copper alloy die casting for parts requiring high strength, thermal conductivity, and electrical conductivity, typically used in electrical connectors, automotive components, and marine applications.

Lead-Free Alloys: Offer lead-free die casting for environmentally-friendly and compliant solutions, especially for industries needing non-toxic materials, such as in food-grade applications or medical devices.

4. Die Casting Production and Manufacturing

Mass Production: Provide high-volume mass production die casting services for parts used in industries like automotive, electronics, and consumer products. This includes batch runs, ensuring consistency and efficiency in large quantities.

Small Batch Production: Offer small batch die casting for industries that need shorter production runs, such as prototypes or limited-edition products.

Complex Shape Casting: Specialize in die casting parts with complex geometries, including thin walls, fine details, and intricate features for industries like aerospace, medical devices, and electronics.

Precision Die Casting: Offer high-precision die casting services to create parts with tight tolerances, such as those used in precision engineering, medical equipment, and electronics.

5. Finishing and Secondary Services

Surface Finishing: Provide post-casting surface finishing services like polishing, deburring, graining, shot blasting, and sandblasting to enhance the aesthetic appearance and functional properties of the die-cast parts.

Machining: Offer machining services like CNC milling, CNC turning, and drilling to add fine details and achieve precise dimensions after the die casting process.

Painting and Coating: Provide painting, powder coating, and electroplating services to add color, improve the appearance, or provide additional corrosion resistance.

Heat Treatment: Offer heat treatment services to improve the mechanical properties of die-cast parts, such as hardness, strength, and fatigue resistance. This may include annealing, quenching, or tempering.

Tapping and Threading: Offer tapping and threading services to add internal and external threads to die-cast parts, which is often required for fasteners or assemblies.

6. Quality Control and Testing

Dimensional Inspection: Provide dimensional inspection services to ensure that die-cast parts meet the required tolerances and specifications, using coordinate measuring machines (CMMs) and optical measurement tools.

Non-Destructive Testing (NDT): Offer NDT services such as X-ray inspection, ultrasonic testing, and die penetrant testing to detect internal defects like voids, porosity, and cracks in die-cast parts.

Mechanical Property Testing: Provide testing services to assess strength, hardness, ductility, and impact resistance of the cast parts, ensuring they meet industry standards and customer specifications.

Porosity Testing: Perform porosity testing to detect air bubbles and voids inside the die-cast parts, which can affect the part's strength and performance.

Thermal Cycling Tests: Offer thermal cycling tests to assess the durability of die-cast parts under extreme temperature fluctuations, often necessary for automotive and aerospace applications.

7. Sustainability and Environmentally Friendly Die Casting

Recycled Materials: Provide die casting services using recycled metals like aluminum and zinc, helping customers achieve sustainability goals while maintaining high-quality standards.

Eco-friendly Die Casting: Implement environmentally friendly practices, such as using non-toxic coatings, low-emission processes, and energy-efficient machinery, to reduce the environmental impact of the die-casting operation.

Zero-Waste Practices: Offer zero-waste die casting services, ensuring that scrap metal and other by-products are properly recycled or repurposed, contributing to a circular economy.

8. Die Casting Tool Maintenance and Repair

Tool Design Optimization: Offer services to improve and optimize casting dies for longer life and better efficiency. This includes redesigning tool components that experience high wear and tear.

Die Repair Services: Provide die repair services to fix issues like cracks, wear, or damage in the die tools to ensure the continued quality of casting.

Tooling Maintenance: Offer routine tooling maintenance services to ensure the longevity and precision of the die-casting tools and maintain consistent part quality throughout the production run.

9. Die Casting for Specific Industries

Automotive Die Casting: Specialize in die casting for automotive parts, including engine components, transmission parts, brackets, and heat exchangers, ensuring durability and performance.

Aerospace Die Casting: Provide die-cast components for the aerospace industry, including aircraft parts, turbine components, and control systems, ensuring lightweight and strong parts that meet aerospace standards.

Medical Device Die Casting: Offer precision die-cast components for medical devices like surgical instruments, prosthetics, implants, and diagnostic equipment, ensuring high-quality, reliable parts.

Electronics Die Casting: Provide die casting for electronic enclosures, connectors, heat sinks, and housing parts for the consumer electronics industry, offering both functional and aesthetic solutions.

Consumer Products: Offer die casting for high-quality consumer goods like appliance parts, decorative items, and hardware components, ensuring design flexibility and performance.

[ Retract  ]

]