In Robotics and Automation, improvements are continuously made to enhance performance, efficiency, safety, and scalability. These improvements are categorized across various aspects of technology, design, integration, and deployment. Below are the categories of improvements in Robotics & Automation:

1. Robotic Design and Hardware

Advanced Materials: The use of lightweight, durable materials like carbon fiber, advanced polymers, and metals (e.g., titanium) is improving the robustness, weight, and performance of robotic systems. These materials enhance the endurance and agility of robots while reducing energy consumption.

Miniaturization: Miniaturized robotic components are enabling the development of smaller, more compact robots. This makes robots more adaptable to tight spaces and allows for mobile or wearable applications in fields like healthcare and consumer electronics.

Modular Design: Advances in modular robotic systems allow for easy configuration, reconfiguration, and scaling. This means a robotic system can be customized to meet specific application needs by adding or removing modules (e.g., arms, sensors).

Energy-Efficiency: Improvements in battery technology and power management systems have led to more energy-efficient robots, allowing them to work longer and reduce the frequency of recharging or downtime.

Collaborative Robots: Development of collaborative robots that can work alongside humans in a shared environment, increasing safety and productivity. These robots are designed with advanced sensors and safety features that prevent accidents while interacting with workers.

2. Artificial Intelligence (AI) and Machine Learning

Vision Systems: AI-powered vision systems have greatly improved robotic perception, allowing robots to identify objects, navigate environments, and even make decisions based on visual input. This enables robots to perform complex tasks such as quality control and sorting.

Autonomous Decision-Making: Robots are becoming more capable of making autonomous decisions based on real-time data and environmental inputs, improving flexibility and reducing the need for human intervention. Reinforcement learning and neural networks are often applied to this development.

Natural Language Processing (NLP): Integration of natural language processing allows robots to understand and respond to spoken commands or instructions, enhancing ease of use and human-robot interaction.

AI Algorithms for Path Planning: Advances in AI algorithms have improved the ability of robots to efficiently navigate and optimize their movement paths, especially in complex environments. This is particularly important in autonomous mobile robots (AMRs) and drones.

3. Robotic Software and Programming

Intuitive User Interfaces: Software improvements have made robot programming and control more accessible with graphical interfaces, drag-and-drop programming, and visual simulation tools, reducing the need for highly specialized programming skills.

Robot Operating Systems (ROS): The evolution of Robot Operating Systems (ROS) has standardized robot software frameworks, enabling easier integration, communication, and collaboration among different robots and systems.

Cloud-Based Robotics: The integration of cloud computing into robotics enables remote management, data processing, and system updates, allowing robots to share data and collaborate in real time across distributed networks.

Edge Computing: Advances in edge computing allow robots to process data locally, reducing latency and improving real-time decision-making for tasks like navigation, object recognition, and sensor fusion.

Robotic Simulation: Improved simulation software enables more accurate virtual testing of robots in a controlled environment before physical deployment, reducing the risk of failure and improving system performance.

4. Sensors and Perception

Advanced Sensors: Developments in sensor technologies such as LIDAR, radar, ultrasonic, and advanced cameras are improving the ability of robots to perceive and understand their surroundings with greater accuracy, enabling better navigation, manipulation, and safety.

Force and Tactile Sensing: Force/torque sensors and tactile feedback allow robots to manipulate delicate or sensitive objects more safely and with greater precision, improving applications in fields like surgery or assembly.

Multi-Sensor Fusion: Improved techniques in sensor fusion enable robots to combine data from multiple sources (e.g., visual, auditory, and tactile sensors) to build a more comprehensive understanding of their environment and make better decisions.

Environmental Awareness: Robotic systems are becoming increasingly capable of sensing and adapting to dynamic environments, such as changes in lighting, temperature, or obstacles, through real-time data processing.

5. Robotic Motion and Manipulation

Precision and Dexterity: Advances in robotic actuators and robotic hands have made robots more precise and dexterous. Soft robotics and bio-inspired designs have also enabled robots to perform highly flexible, human-like motions, suitable for complex tasks like delicate surgery or high-precision assembly.

Enhanced Grippers and End Effectors: New designs for robotic grippers (such as adaptive, soft, or multi-fingered grippers) provide more capabilities for gripping and manipulating various objects with different shapes, sizes, and materials.

Dynamic Movement: Improved algorithms and hardware are enabling robots to perform more dynamic movements, such as jumping, running, or even dancing, with better balance, speed, and agility. This opens up new applications in robotic exoskeletons and autonomous vehicles.

Multi-Robot Coordination: Advancements in multi-robot systems allow robots to collaborate seamlessly, working together to achieve complex tasks more efficiently. This includes swarming behavior used in logistics or search-and-rescue operations.

6. Human-Robot Interaction (HRI)

Safety Enhancements: Improvements in safety sensors (e.g., vision, proximity, force sensors) have allowed robots to safely interact with humans in collaborative work environments, preventing accidents and improving safety during physical interaction.

Haptic Feedback: Advanced haptic feedback systems allow humans to feel the robot's actions, enabling more intuitive control and interaction. This is especially beneficial in remote operations or teleoperation of robots in hazardous environments.

Voice and Gesture Control: Integration of voice and gesture recognition systems enables operators to communicate and control robots through natural gestures or speech, simplifying interaction and making robots more accessible in dynamic environments.

Emotional Intelligence: Research into robotic emotional intelligence aims to improve the way robots recognize and respond to human emotions, fostering better collaboration and reducing social friction, particularly in healthcare, customer service, and elder care.

7. Industry-Specific Robotics

Healthcare Robotics: In the medical industry, improvements include robots for minimally invasive surgery, robotic prosthetics, robotic exoskeletons, and rehabilitation devices. These advancements improve the precision, effectiveness, and accessibility of healthcare treatments.

Agricultural Robotics: Robots designed for agricultural applications (e.g., autonomous tractors, harvesters, and planting robots) are improving crop yield, reducing labor costs, and enhancing efficiency in the farming industry.

Logistics and Warehouse Robotics: The use of autonomous mobile robots (AMRs) and robotic arms in warehouses for inventory management, order picking, and sorting has streamlined the supply chain, improving both productivity and accuracy in order fulfillment.

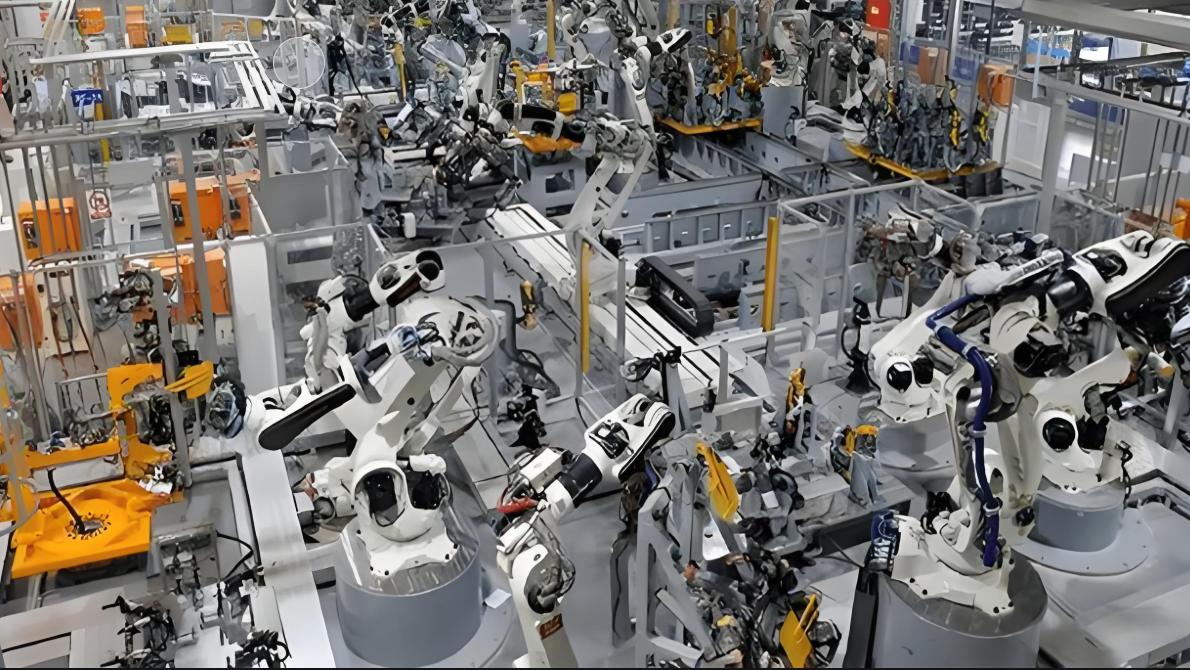

Manufacturing Automation: Collaborative robots and robotic arms are increasingly used in manufacturing to assist with tasks such as assembly, painting, welding, and inspection, improving quality control and production efficiency.

8. Robotic Mobility and Autonomy

Autonomous Vehicles: Advances in robotics for autonomous vehicles, including self-driving cars, trucks, and drones, enable smarter navigation, decision-making, and interaction with the environment for better safety and operational efficiency.

Autonomous Mobile Robots (AMRs): Improvements in AMRs for industrial use allow for more efficient warehouse logistics, material handling, and transport in environments that require complex decision-making and autonomous movement.

Drones and UAVs: Continued advancements in drone technology have enhanced their ability to navigate complex environments, capture high-definition data, and perform autonomous tasks in industries such as agriculture, delivery, infrastructure inspection, and surveillance.

9. Integration with Other Technologies

Internet of Things (IoT): Robotics is increasingly integrated with the IoT to enable real-time data exchange between robots and other devices or systems. This enables smarter coordination and optimization of tasks across an entire network of devices.

Blockchain for Robotics: Blockchain technology is being explored for enhanced security and traceability of robotic operations, particularly in scenarios where autonomous robots are handling sensitive information or tasks.

5G Connectivity: The advent of 5G networks is enabling faster and more reliable communication between robots and control systems, allowing for real-time monitoring, coordination, and control in remote or large-scale operations.

10. Sustainability in Robotics

Eco-friendly Manufacturing: As robots become more widely used, manufacturers are focusing on sustainable materials and energy-efficient design principles, reducing waste and the environmental footprint of robotic systems.

Recycling and Reuse: Improvements in robotics recycling programs and efforts to design robots for easy disassembly are helping to minimize the impact of end-of-life disposal and encourage the reuse of components.

In Robotics and Automation, improvements are continuously made to enhance performance, efficiency, safety, and scalability. These improvements are categorized across various aspects of technology, design, integration, and deployment. Below are the categories of improvements in Robotics & Automation:

1. Robotic Design and Hardware

Advanced Materials: The use of lightweight, durable materials like carbon fiber, advanced polymers, and metals (e.g., titanium) is improving the robustness, weight, and performance of robotic systems. These materials enhance the endurance and agility of robots while reducing energy consumption.

Miniaturization: Miniaturized robotic components are enabling the development of smaller, more compact robots. This makes robots more adaptable to tight spaces and allows for mobile or wearable applications in fields like healthcare and consumer electronics.

Modular Design: Advances in modular robotic systems allow for easy configuration, reconfiguration, and scaling. This means a robotic system can be customized to meet specific application needs by adding or removing modules (e.g., arms, sensors).

Energy-Efficiency: Improvements in battery technology and power management systems have led to more energy-efficient robots, allowing them to work longer and reduce the frequency of recharging or downtime.

Collaborative Robots: Development of collaborative robots that can work alongside humans in a shared environment, increasing safety and productivity. These robots are designed with advanced sensors and safety features that prevent accidents while interacting with workers.

2. Artificial Intelligence (AI) and Machine Learning

Vision Systems: AI-powered vision systems have greatly improved robotic perception, allowing robots to identify objects, navigate environments, and even make decisions based on visual input. This enables robots to perform complex tasks such as quality control and sorting.

Autonomous Decision-Making: Robots are becoming more capable of making autonomous decisions based on real-time data and environmental inputs, improving flexibility and reducing the need for human intervention. Reinforcement learning and neural networks are often applied to this development.

Natural Language Processing (NLP): Integration of natural language processing allows robots to understand and respond to spoken commands or instructions, enhancing ease of use and human-robot interaction.

AI Algorithms for Path Planning: Advances in AI algorithms have improved the ability of robots to efficiently navigate and optimize their movement paths, especially in complex environments. This is particularly important in autonomous mobile robots (AMRs) and drones.

3. Robotic Software and Programming

Intuitive User Interfaces: Software improvements have made robot programming and control more accessible with graphical interfaces, drag-and-drop programming, and visual simulation tools, reducing the need for highly specialized programming skills.

Robot Operating Systems (ROS): The evolution of Robot Operating Systems (ROS) has standardized robot software frameworks, enabling easier integration, communication, and collaboration among different robots and systems.

Cloud-Based Robotics: The integration of cloud computing into robotics enables remote management, data processing, and system updates, allowing robots to share data and collaborate in real time across distributed networks.

Edge Computing: Advances in edge computing allow robots to process data locally, reducing latency and improving real-time decision-making for tasks like navigation, object recognition, and sensor fusion.

Robotic Simulation: Improved simulation software enables more accurate virtual testing of robots in a controlled environment before physical deployment, reducing the risk of failure and improving system performance.

4. Sensors and Perception

Advanced Sensors: Developments in sensor technologies such as LIDAR, radar, ultrasonic, and advanced cameras are improving the ability of robots to perceive and understand their surroundings with greater accuracy, enabling better navigation, manipulation, and safety.

Force and Tactile Sensing: Force/torque sensors and tactile feedback allow robots to manipulate delicate or sensitive objects more safely and with greater precision, improving applications in fields like surgery or assembly.

Multi-Sensor Fusion: Improved techniques in sensor fusion enable robots to combine data from multiple sources (e.g., visual, auditory, and tactile sensors) to build a more comprehensive understanding of their environment and make better decisions.

Environmental Awareness: Robotic systems are becoming increasingly capable of sensing and adapting to dynamic environments, such as changes in lighting, temperature, or obstacles, through real-time data processing.

5. Robotic Motion and Manipulation

Precision and Dexterity: Advances in robotic actuators and robotic hands have made robots more precise and dexterous. Soft robotics and bio-inspired designs have also enabled robots to perform highly flexible, human-like motions, suitable for complex tasks like delicate surgery or high-precision assembly.

Enhanced Grippers and End Effectors: New designs for robotic grippers (such as adaptive, soft, or multi-fingered grippers) provide more capabilities for gripping and manipulating various objects with different shapes, sizes, and materials.

Dynamic Movement: Improved algorithms and hardware are enabling robots to perform more dynamic movements, such as jumping, running, or even dancing, with better balance, speed, and agility. This opens up new applications in robotic exoskeletons and autonomous vehicles.

Multi-Robot Coordination: Advancements in multi-robot systems allow robots to collaborate seamlessly, working together to achieve complex tasks more efficiently. This includes swarming behavior used in logistics or search-and-rescue operations.

6. Human-Robot Interaction (HRI)

Safety Enhancements: Improvements in safety sensors (e.g., vision, proximity, force sensors) have allowed robots to safely interact with humans in collaborative work environments, preventing accidents and improving safety during physical interaction.

Haptic Feedback: Advanced haptic feedback systems allow humans to feel the robot's actions, enabling more intuitive control and interaction. This is especially beneficial in remote operations or teleoperation of robots in hazardous environments.

Voice and Gesture Control: Integration of voice and gesture recognition systems enables operators to communicate and control robots through natural gestures or speech, simplifying interaction and making robots more accessible in dynamic environments.

Emotional Intelligence: Research into robotic emotional intelligence aims to improve the way robots recognize and respond to human emotions, fostering better collaboration and reducing social friction, particularly in healthcare, customer service, and elder care.

7. Industry-Specific Robotics

Healthcare Robotics: In the medical industry, improvements include robots for minimally invasive surgery, robotic prosthetics, robotic exoskeletons, and rehabilitation devices. These advancements improve the precision, effectiveness, and accessibility of healthcare treatments.

Agricultural Robotics: Robots designed for agricultural applications (e.g., autonomous tractors, harvesters, and planting robots) are improving crop yield, reducing labor costs, and enhancing efficiency in the farming industry.

Logistics and Warehouse Robotics: The use of autonomous mobile robots (AMRs) and robotic arms in warehouses for inventory management, order picking, and sorting has streamlined the supply chain, improving both productivity and accuracy in order fulfillment.

Manufacturing Automation: Collaborative robots and robotic arms are increasingly used in manufacturing to assist with tasks such as assembly, painting, welding, and inspection, improving quality control and production efficiency.

8. Robotic Mobility and Autonomy

Autonomous Vehicles: Advances in robotics for autonomous vehicles, including self-driving cars, trucks, and drones, enable smarter navigation, decision-making, and interaction with the environment for better safety and operational efficiency.

Autonomous Mobile Robots (AMRs): Improvements in AMRs for industrial use allow for more efficient warehouse logistics, material handling, and transport in environments that require complex decision-making and autonomous movement.

Drones and UAVs: Continued advancements in drone technology have enhanced their ability to navigate complex environments, capture high-definition data, and perform autonomous tasks in industries such as agriculture, delivery, infrastructure inspection, and surveillance.

9. Integration with Other Technologies

Internet of Things (IoT): Robotics is increasingly integrated with the IoT to enable real-time data exchange between robots and other devices or systems. This enables smarter coordination and optimization of tasks across an entire network of devices.

Blockchain for Robotics: Blockchain technology is being explored for enhanced security and traceability of robotic operations, particularly in scenarios where autonomous robots are handling sensitive information or tasks.

5G Connectivity: The advent of 5G networks is enabling faster and more reliable communication between robots and control systems, allowing for real-time monitoring, coordination, and control in remote or large-scale operations.

10. Sustainability in Robotics

Eco-friendly Manufacturing: As robots become more widely used, manufacturers are focusing on sustainable materials and energy-efficient design principles, reducing waste and the environmental footprint of robotic systems.

Recycling and Reuse: Improvements in robotics recycling programs and efforts to design robots for easy disassembly are helping to minimize the impact of end-of-life disposal and encourage the reuse of components.

[ Retract  ]

]

地址

地址